To realize a gapless material tracking the monitoring of material movments on roller tables and cooling beds is an important task. LogoTek supplies and installs the necessary sensors and control equipment to solve this task. The delivery scope includes software for roller table control and HMI on basis of SIMATIC WinCC

Crane Tracking Systems are used to detect actual position and load changes of cranes. As component of the warehous emanagement system these systems are used for a gapless mapterial tracking. LogoTek develops, manufactures and installs complete tracking systems for the tracking of slabs, coils, heavy plates and other steel products. The system can be retrofitted or installed on new cranes.

For the position detection of the cranes we are using different kinds of positioning systems. In most applications reliable laser devices will be installed, that are equipped with robust protection housings that enable operation in environments of up to 80°C temperature. In long halls, or in extremly dusty or foggy areas (like continuous casting halls) the use of the SYMEO LPR® positioning system is recommended. LPR® is extremely robust and suitable for free moving vehicles like fork lifts.

Application note: Crane Tracking System for Coil Yard at Erdemir

Application note: Crane tracking System for slab yard at China Steel Co.

Application note: Benefits of a Crane Tracking System

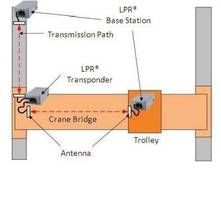

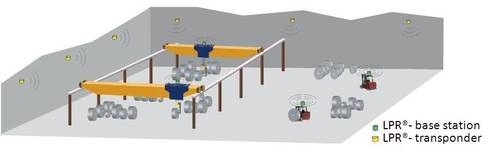

The SYMEO LPR® positionioning technology is suitable for the position detection of cranes and free moving vehicles like fork lifts. LPR® ist based on the run time detection of 5GHz pulse signals that are sent from stationary transponders to a mobile base station on the vehicle. In difference to laser systems this position technolgy is also suitable in outdoor areas, rain and fog, and in extremly dusty environments. LogoTek has realized LPR®-1D and LPR®2D applications in Germany and abroad.

Especially for the position detection of vehicles that have to move between halls and outdoor areas LPR® is the perfect choice. To reduce the effort for the outdoor installationn the LPR® -system can be combined with Differential-GPS receivers. Inside of halls the LPR® delivers the position information, while the GPS- system is active when the vehicle is operating under open sky.

The LogoTek vehicle client controls the communication to the positioning devices, and it also transfers the GPS reference information, and is showing the yard contents in a graphical view.

The advantages of the LPR® system are: - Resistable to dust, steam and other partcles in the air

- Minium maintenance effort

- High temperature-resistant (-40°C to 75 °C)

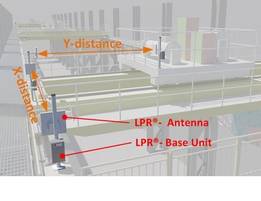

The positioning system for each crane is consisting of 2 base stations (1 base station on trolley, 1 base station at the end of the hall/ adjacent crane) and one transponder (installed on the crane bridge). The data of the X- and Y- coordinates are available on each of the three components via ethernet. These three stations with their antennas are forming one group, which uses one seperate radio channel on its own.

The position detection system basically consists (for each crane) of: - 2x base stations

- 1x transponder stations

- 4x planar antennas

The distance is determined by measuring the transit time of radio signals. The transponder transmits defined time slots to the base station in order to set the time when a distance measurement is about to start. Therefore, the transponder transmits at first a communication package to the base station the measurement should be done with. The chosen station transmits in return a sequence of response as well as a special, wide-band and thus for the distance measurement well suited response signal. Based on this signal, the transponder synchronizes itself and responds highly synchronous with exactly the same signal according to an accurately known time. The base station receives this signal and determines the distance to the transponder via transit time.

The distance can be readout after the measurement at each within the system involved LPR® unit (base stations, transponders). It is optionally possible to activate a potential-free switch contact after falling below a specific distance, such as triggering a warning signal. With that, the LPR®-1D system could be as well used as a collision detection system for the collision prevention of two cranes, which are moving towards each other.

Technical Data - Frequency range: 5,725-5,875 GHz, ISM-Band

- Output Power: max. 0,025 W EIRP

- Measuring distance: up to 1800 m

- Typical accuracy: up to ±5 cm

- Update rate: up to 30 Hz

- Voltage: 10-36 V DC

- Ambient temperature: -40°C to +75°C

- Protection class: up to IP65

- Housing dimensions (LxWxH): 260 x 160 x 91 mm

- Data interface: Symeo 1D binary protocol

- External connector type: cable gland, internal terminal block

- Antennas: up to 4 independent antennas, N-Connector

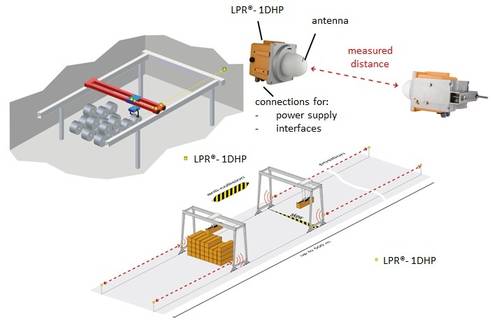

The LPR®-1DHP is a highly-precise solution for measurements over long distances and for anti-collision. The sensors are accurate to ±1 cm at a range of up to 500 metres. The measurement unit and antennas are integrated in a compact housing to ensure extremely simple installation without the need for complicated, time-comsuming alignment. A rough alignment of the units to each other is even at longer distances and with uneven crane runways more than sufficient.

The technology is based on measuring the duration of a 61 GHz signal via the round trip time between two sensor units. Wifi data networks at 2.4 and 5.7 GHz can be operated in parallel at any time without the risk of interference. Due to the combination of two measured pairs it is possible to detect the complete 2D-position of the crane trolley dynamically in real-time. The sensors are maintenance-free and able to withstand harsh weather, dirt, grime and vibrations.

In addition to the measured distance it is even possible to display the relative velocity of the moving sensores simultaneously. As an option , the measurement data and the switching contacts can be accessed on both LPR®-1DHP units when they are operating at a reduced measurement rate.

Technical Data - Frequency range: 61,0 - 61,5 GHz, ISM-Band

- Output Power: max. 0,1 W EIRP

- Measuring distance: up to 500 m

- Typical accuracy: up to ±1 cm

- Update rate: up to 25 Hz

- Voltage: 10-36 V DC

- Ambient temperature: -40°C to +75°C

- Protection class: up to IP65

- Housing dimensions (LxWxH): 205 x 140 x 140 mm

- Data interface: Symeo ASCII binary protocol

- External connector type: Ethernet housing connector, other interfaces via cable gland

- Antennas: integrated

A gapless material tracking often requires the integration of in an open field driving/moving vehicles (forklift, kress-carrier). Particularly in the position detection of vehicles, which are mostly operating in indoors and outdoors or even under harshest industrial conditions or sections, the LPR®-2D system offers invaluable and significant benefits in comparison to other positioning technolgy.

The LPR®-2D System enables the exact position by measuring the distance between base stations (on moving objects) and fixed reference marks, the so-called transponders, in order to compute their current position and heading angle. Determining a position requires contact with at least three transponders.

The LPR®-2D System is easily adapted to local conditions and the transponders can be mounted at varying heights and distances from each other. With a typical arrangement, the full position detection functionality is maintained even if contact to a transponder is interrupted. The reliability of the maintenance-free sensors is not affected by heavy contamination or vibrations.

Technical Data - Frequency range: 5,725-5,875 GHz, ISM-Band

- Output Power: max. 0,025 W EIRP

- Measuring distance: up to 400 m

- Typical accuracy: up to ±5 - 20 cm

- Update rate: up to 20 Hz

- Voltage: 10-36 V DC

- Ambient temperature: -40°C to +75°C

- Protection class: up to IP65

- Housing base station (LxWxH): 260 x 160 x 91 mm

- Housing transponder (LxWxH): 281 x 125 x 150 mm

- Data interface: Symeo ASCII protocol

- External connector type: 2 antenna connectors N-type, Ethernet housing connector, voltage and interfaces via cable gland

- Antennas: up to 2 independent antennas, N-Connector

LogoTek is supplier of complex automation systems for various production areas in the heavy industries. The delivery scope of this systems includes PLC hardware, frequency inverters and drive electronics, electrical cabinets as well as PLC software.

LogoTek has references for projects in the application fields of material tracking, roller table control with frequnecy inverters, crane control systems, complex operator panels with HMI functions, control of marking machines, subsitution of Siemens S5 PLCs with S7.

Hardware platforms

SIMATIC S7-300 und S7-400

SIMATIC S5

VIPA PLCs and I/O boards

Industrial Ethernet

Frequency inverters and synchronuous drive control

WLAN

Profibus and other field bus systems

Software

Step 7

WinCC

PCS7

CITECT

ODBC-Database communication

OPC-process communication

The Warehouse Management System is the key component of the material tracking in a heavy industrial plant. LogoTek offers complete solutions for the warehouse management, including database server, client software and complete hardware for communication and HMI.

A Warehouse Management System can include: - Server with database (Oracle or MS SQL-Server)

- Client-Software for cranes

- Client-Software for yard operator PCs

- Client-Software for mobiel data transmission devices (PDA)

- Software processes for communication with Layer 3(PPS/MES) and Layer 4 (ERP)

- Software processes for communication with basic automation systems (Layer 1)

An important component of LogoTek systems are often Data Akquisition Terminals and Industrial PDA. Depending on the application reuirements these devices can be compact PDA with Windows Mobile/CE operating system, or powerful handheld devices with Embedded XP or Linux Operating System.

|

| |

March 2014 - Valin ArcelorMittal Automotive Steel Co.,Ltd.(VAMA) awards a contract for material tracking to LogoTek

Beyond this, there will be eventhough installed a crane tracking system on each of the in total 18 cranes and a wireless-LAN-communication. LogoTek-Software will be in addition responsible for the tracking of the material transportations and for booking the coils in its new locations. ...read more

September 2013 - Big Order from Taiwan

The Formosa Plastics Group from Taipeh/Taiwan just decided to put the responsibility in terms of the technology for material tracking for their new steelworks in Vietnam into the hands of LogoTek....read more

August 2013 - Extension of the heavy plate logistic system in Duisburg

Four additional halls and seven cranes will be integrated in the yet existing yard management system. ...read more

June 2013 - LogoTek gets a contract for an optical identification system for steel billets

The Dragon Steel Corporation,a subsidiary of the biggest steel manufacturer in Taiwan the China Steel Co., just ordered LogoTek with the delivery of a system for the identification of steel billets. ...read more

April 2013 - ThyssenKrupp Steel Europe AG just ordered LogoTek with the delivery of a marking machine for heavy plates

LogoTek will be responsible for the technical construction, manufacturing, installation and commissioning of the marking machine. ...read more

News-Archiv

|

|